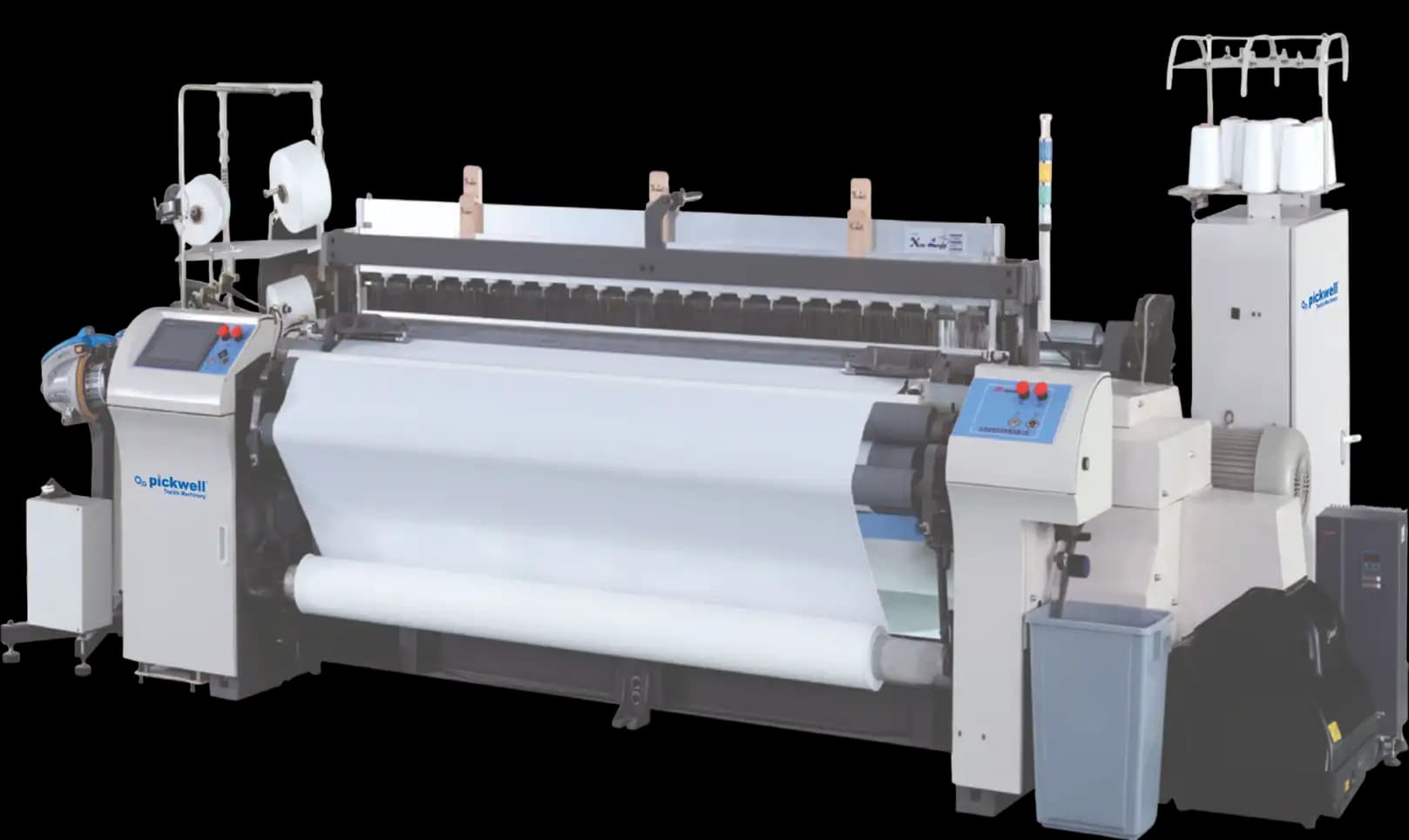

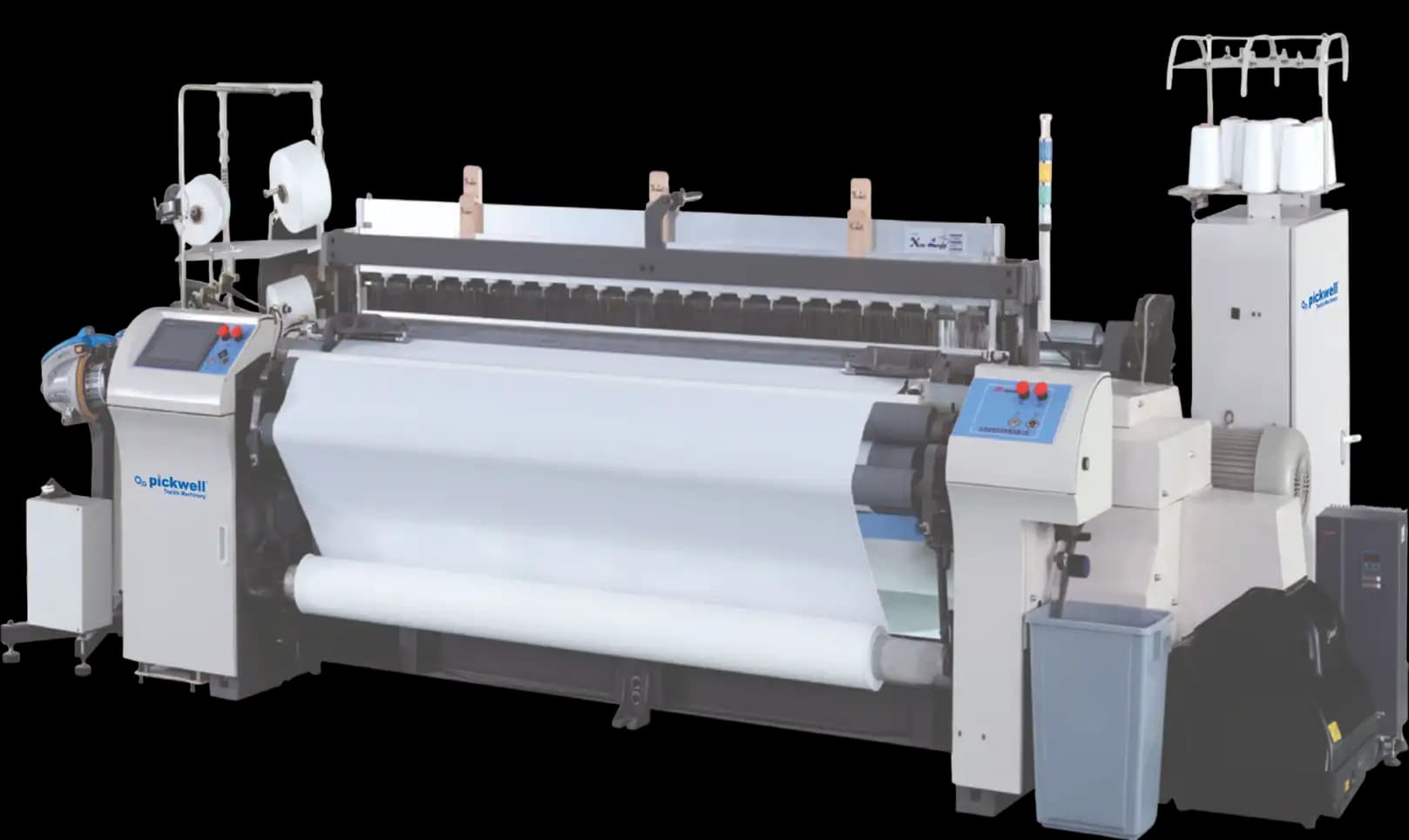

AIRJET LOOMS

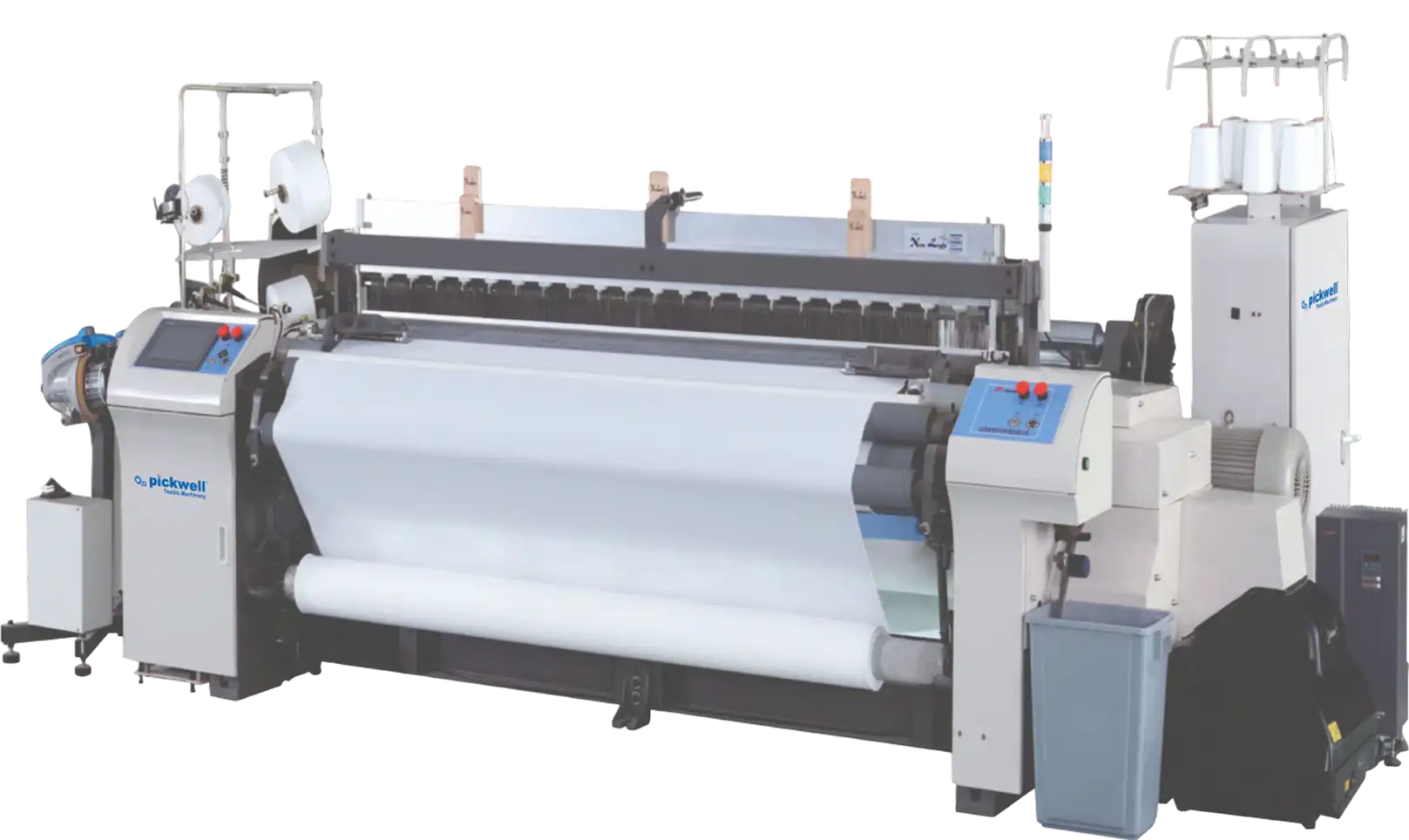

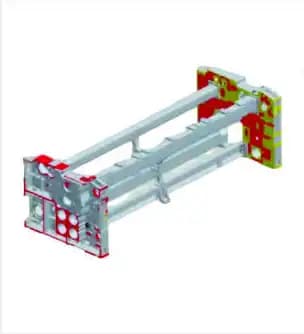

New Designed Frame Structure

Adopts high rigid frame structure, big diameter beam gear and positive let-off driving beam with bath lubrication, which make loom suit for the high density fabric at high speed. Both side cam box and board frame structure have been optimized.

Beating Dynamic Balance System

The beating axis adopted new designed beating dynamic balance system, it improved the beating-up force of the loom, and the vibration of the whole machine is reduced, it is more effectively ensured to weave the high-count and highdensity fabric.

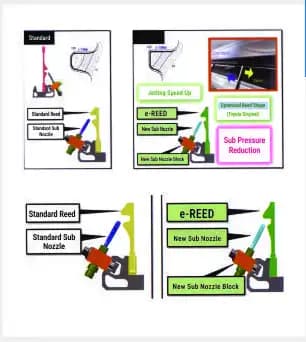

Smart Air Distribution

Dual air tank (1/3 & 2/3) in the sub nozzle, four tank for main nozzle and a reserve tank (total of 7 tanks). Optimized airflow for uninterrupted weaving. Boosts weaving efficiency while lowering air consumption.

E-Feed for Energy Efficiency

Precision-engineered E-Feed. Optimizes air usage and reduces waste. Significantly cuts down operational costs. Adjustable nozzle block for E-reed & Profile reed. Effortless switching for diverse fabric types.

Electronic shedding

The servo motor can independently control the parameters of each heald frame. Users can make changes freely via the control panel. It improves the adaptability of the loom to the varieties of fabrics.

Network Application

With powerful network functions, all the working status, efficiency, production and various parameters can be read online.

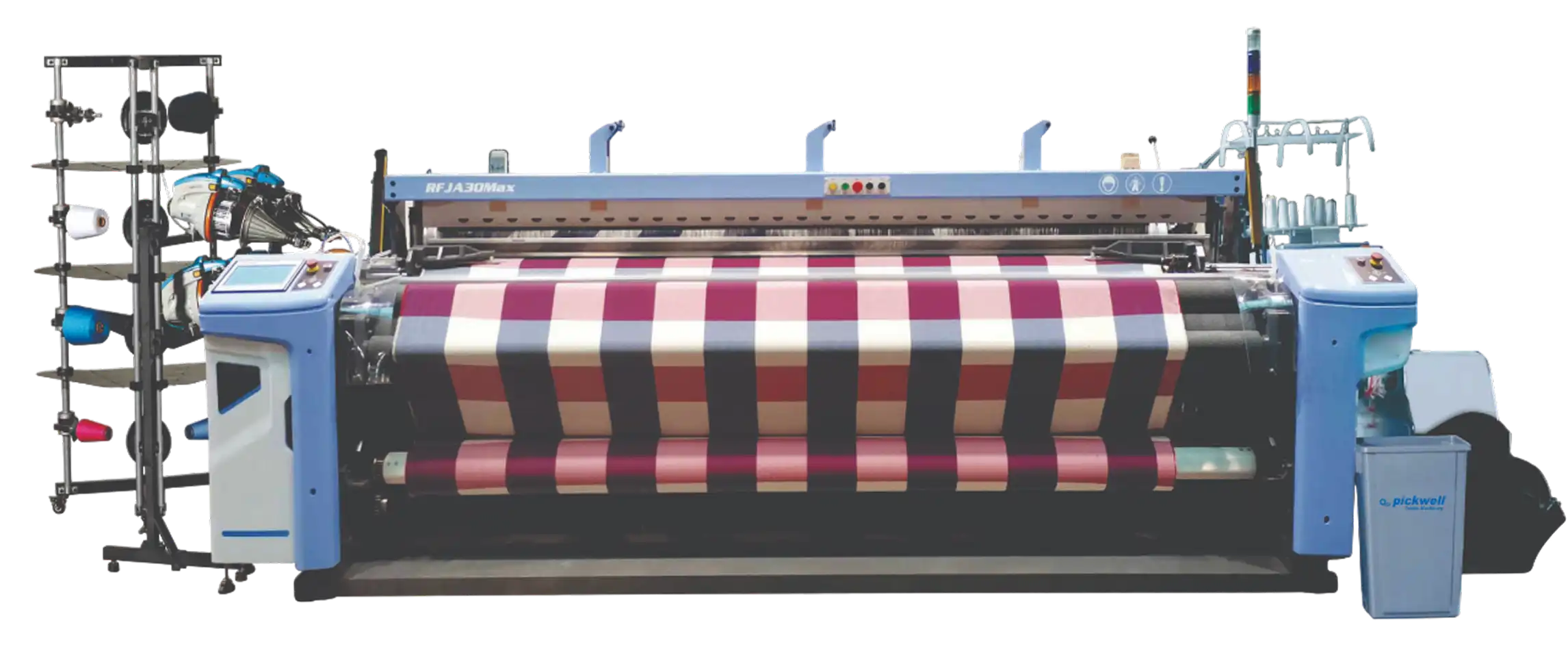

Simple Operation Performance

The Simple operation concept is reflected on every details of RFJA30Max, everybody can operate easily.

High Speed & Low Vibration

More suitable design on warp yarn path position and beating dynamic balance system highly reduced the vibration and noise, it helps to realize higher speed working.

RFJA30Max air jet loom is developed by our company which has advanced performance on the base of the merit of RFJA30, it is developed for meeting higher weaving requirement.

- Integral high-precision wall plate, once clamping molding, strong homogeneity.

- Short stroke high-precision conjugate cam weft insertion, the weft draw-in time while ensuring high speed, low vibration and low energy consumption.

- New type of balanced weft-beating mechanism effectively reduces the vibration of the loom at high speed.

- The main drive adopts electric spindle direct drive mechanism, high efficiency and energy saving.

- New opening mechanism and warp position line, energy saving and production increase for customers.

- Continuously optimized energy efficient weft draw-in system can save about 30% of air consumption for customers.

- Humanize intelligent electronic control system, effectively realizing the centralized control and management of the machine group in the workshop.

Contact Form

For inquiries, please reach out to us.

Contact Details

Contact us on below details for more information.